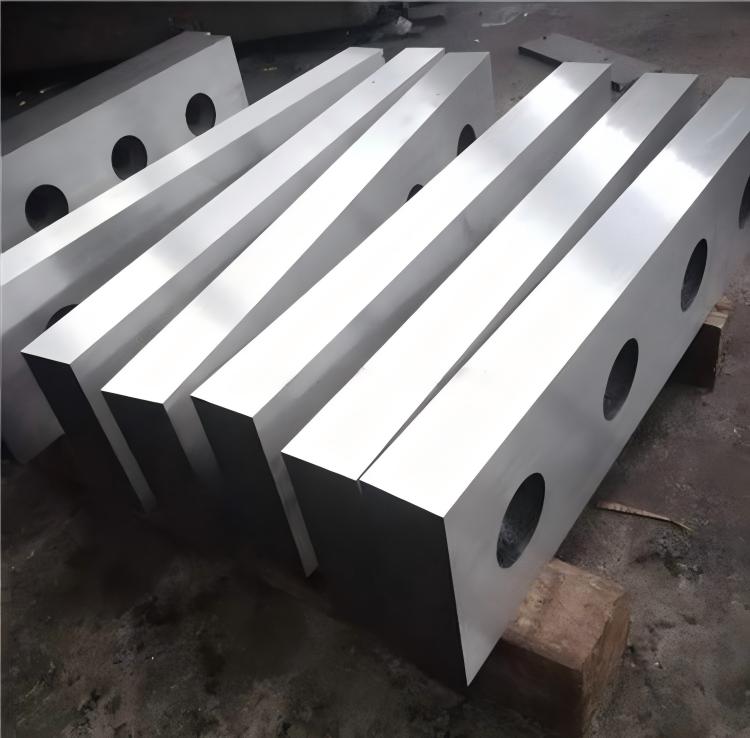

Lame de cisaille extra longue de haute précision Les lames de cisaillement jouent un rôle essentiel dans l'industrie métallurgique. Le choix et l'utilisation du bon matériau jouent un rôle clé dans leur performance et leur durée de vie. Dans cet article, nous approfondirons la sélection et l'utilisation des lames de cisaillement afin de vous aider à mieux comprendre comment choisir et entretenir ces composants essentiels.

Sélection des matériaux : choisir le bon matériau

Sélection du matériau de la lame

Les lames de cisaillement doivent généralement présenter une bonne résistance à l'usure, une bonne dureté et une bonne rigidité, car leur fonction principale est de cisailler des tôles. Voici quelques matériaux de lames courants :

Acier à outils : L'acier à outils est un matériau de lame courant qui présente une bonne dureté et une bonne résistance à l'usure et qui convient aux tâches de cisaillement générales.

Acier allié : l'acier allié peut améliorer la résistance et la résistance à la corrosion de la lame tout en offrant dureté et résistance à l'usure, et convient aux situations où une résistance de lame plus élevée est requise.

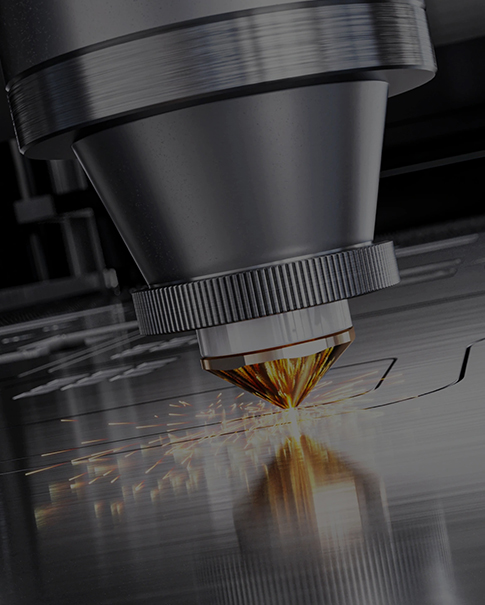

Acier rapide : L'acier rapide a une dureté et une stabilité thermique plus élevées et convient à la coupe et au cisaillement à grande vitesse de matériaux à haute résistance.

Carbure : Les lames en carbure sont très dures et résistantes à l'usure et conviennent aux situations où la durée de vie et les performances de la lame sont extrêmement exigeantes.

Revêtement de lame

Outre le choix du matériau de lame, le revêtement est également un facteur important pour améliorer les performances de la lame. Les revêtements courants incluent le nitrure de titane, l'oxyde d'aluminium et le métal revêtu, qui peuvent améliorer la dureté, la résistance à l'usure et à la corrosion de la lame, et prolonger sa durée de vie.

Utilisation : Fonctionnement et entretien corrects

Compétences opérationnelles correctes

Évitez de surcharger la lame et évitez de couper des matériaux trop épais ou trop durs pour ne pas endommager la lame.

Faites attention au réglage de la vitesse de coupe et de la force de coupe pour éviter d'endommager la lame ou de provoquer une inefficacité causée par une vitesse trop rapide ou trop lente.

Vérifiez régulièrement l'usure de la lame et effectuez l'entretien et le remplacement à temps.

Entretien et soins réguliers

Nettoyez les copeaux de métal et les taches d'huile sur la surface de la lame pour éviter l'accumulation et affecter l'effet de cisaillement.

Affûtez et affûtez régulièrement la lame pour maintenir le tranchant et la géométrie de la lame.

Faites attention au stockage pour éviter l'humidité, les collisions ou la corrosion chimique de la lame.

Le choix et l'utilisation des lames de cisailles sont essentiels pour l'industrie de la transformation des métaux. Choisir le bon matériau, utiliser et entretenir correctement la lame peut améliorer l'efficacité de la production, réduire les coûts et prolonger sa durée de vie. J'espère que cet article vous aidera et vous guidera dans vos pratiques de production. Pour en savoir plus, continuez à suivre les mises à jour de notre blog. Merci de votre lecture !

Site Web : https://www.cnsanqumc.com/

Numéro de contact : +86 17356699004

WhatsApp : +86 17356699004